Aluminium composite panels are composed of two thin, massive aluminium sheets that are bonded to a core of the plastic polyethylene. Together with the plastic core, the aluminium forms a sort of sandwich. That is why the panels are also called aluminium sandwich panels. The two completely different material (metal and non-metal) not only retains the main characteristics of the original materials (metal aluminum and non-metallic polyethylene plastic), but also overcomes the shortcomings of the original materials, thus obtaining many excellent material properties, such as luxury, colorful decoration, weather resistance, corrosion resistance, impact resistance, fire prevention, moisture prevention, sound insulation, heat insulation, and seismic resistance; Lightweight, easy to process, easy to handle and install, and other characteristics.

There are a great advantages of Aluminium Composite Panel

1, Aluminium composite sheets are easy to cut, drill and shape

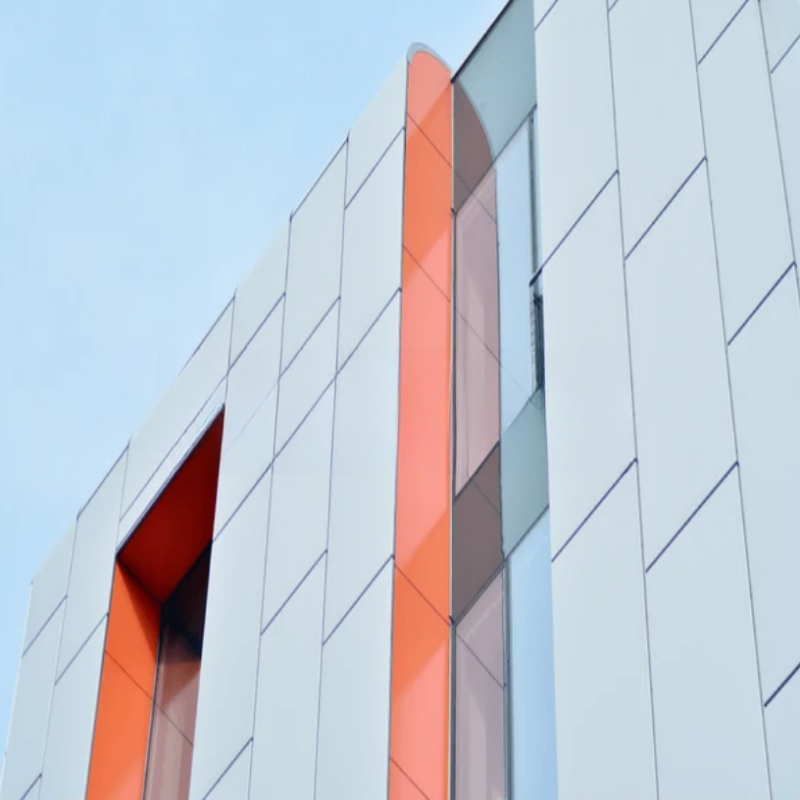

This makes the material a popular choice for a wide range of cladding applications. Aluminium composite sheets can be used to create a striking façade, interiors, signage, modular kitchen or can be used to create subtle, understated cladding. ACP is also lightweight and easy to install, making it a popular choice for both internal and external cladding.

2, Aluminium composite panel is a low maintenance cladding material

When compared to other materials, facade cladding made from aluminum requires less maintenance. For example, wood ages and can peel off, and it needs to be sanded and painted every few years.

3, Aluminium composite panel does not require painting or weatherproofing

ACP sheets are made by sandwiching layers made of aluminum foil with LDPE, gluing them under extreme heat and pressure, and then creating a sturdy, waterproof product that comes in a wide range of styles to make an attractive and cost-effective rain-screen façade.

4, Aluminium composite panel is also a fire resistant cladding material

ACP panels are available in fire-retardant and anti-bacterial variants, making them some of the most preferred cladding materials in the world. Fire-retardant ACP panels are resistant to fire, as they do not conduct heat very quickly, making it an ideal choice for both commercial and residential buildings.

5, Multiple Use Cases

Buildings, particularly those that are completely covered, are a common sight today. As well as external cladding, ACP is also used to construct partitions, false ceilings, and other architectural elements. It is still primarily used for external cladding, although ACP is also used for partitions, false ceilings, and other applications. ACP is a lightweight, weatherproof material that is used extensively in the signage industry as an alternative to heavier, more expensive substrates. Because of its durability, efficiency, flexibility, light weight, ease of processing and forming, it can be used to design more innovative products. ACP is a aluminium sheet that can be painted in any colour, metallic or nonmetallic, as well as patterns that mimic wood or marble in addition to its durability and rigidity.

Parameter of Composite Aluminium Panel

|

Aluminium Skin Layer |

0.05mm, 0.1mm, 0.15mm, 0.2mm, 0.25mm, 0.3mm, 0.4mm, 0.5mm |

|

Panel Thickness |

2mm, 3mm, 4mm, 5mm, 6mm, 7mm |

|

Panel Width |

1220mm, 1250mm, 1550mm, 1570mm, 2000mm |

|

Panel Length |

2440mm, 3200mm, 4000mm, 5000mm, 6000mm,7000mm, 8000mm |

|

Surface |

PE coating, PVDF coating, NANO, Brush surface, Mirror surface |

|

Inner Core |

Normal non toxil PE core |

|

Color |

Solid Matt Color, Solid Glossy Color, Metallic Brushed Color, Marble Grain Color, Wooden Grain Color |

|

Packing & Qty |

LCL packing: wooden pallet package, 100 sheets per pack 1*20’ FT container: 1500 sheets for size 1220*2440mm panel |

Tips and Tricks for Working with ACP

-When cutting ACP, use a sharp knife or Stanley knife. Score the face of the ACP sheet first, then snap the sheet along the score line.

-When drilling ACP, use a sharp HSS drill bit. Start the hole with a small pilot hole, then increase the size of the hole to the desired size.

-When shaping ACP, use a sharp jigsaw. ACP can be easily cut and shaped using standard woodworking tools.

-When installing ACP, use screws or rivets. ACP can be installed using a variety of methods, including screws, rivets or adhesive.

More Projects of Composite Aluminium Panel

- Address

No.3 Beishang New City, GongShu District, Hangzhou China

-

Phone

+86-18072735884

-

Landline

+86-571-88688170

English

English