These are systems in which all the elements that make up the facade system are assembled and installed on the construction site.

In contrast to panel facade systems, classical facades have less manufacturing workmanship, but much more installation workmanship.

Vertical carrier (mullion) profiles and horizontal carrier (transom) profiles form a carrier aluminum carcass that will form the facade plane with anchors that allow 3-dimensional adjustment.Then, the inside of the existing aluminum carcass is glazed and the assembly is completed.

On classic clamshell facades, glass is fixed with aluminum carcass printing and cover profiles. For this reason, these cover profiles are seen when viewed from the outside around the glass plane.

Specification

|

Color |

Matt black; ultra silver; nature clean aluminium; Customized |

|

Functions |

Energy saving, heat & sound insulation, waterproof |

|

Design and dimension |

Custom made |

|

Hardware |

Chinese top brand; Germany brand |

|

Profile |

1.Aluminum alloy 6063-T5,can be thermal break |

|

|

2.Frame thickness:1.2, 1.4, 1.6, 1.8, 2.0mm, normally 1.2mm for windows, 2.0mm for doors |

|

|

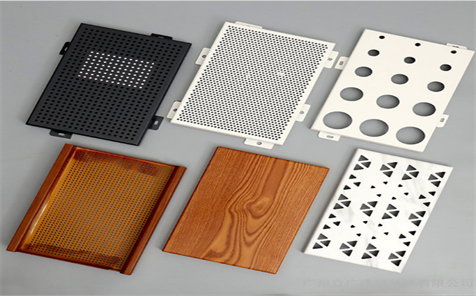

3.Surface finish:Powder coating, Anodized, Electrophoresis, Fluorocarbon coating |

|

Production standard |

Basis on the shop drawings which approved by the buyer |

|

Service |

Professional technical team |

1.Thickness:

PVDF aluminum composite panel comes in various thicknesses. This depends both on the expected reason or utilization of the panel and the brand. As a rule, PVDF covered panels are fairly thicker than the ordinary aluminum composite panels. Just since there is another layer in its structure, these panels are thicker. They come in 3, 4, 5, and 6mm thicknesses. This is the reason PVDF aluminum composite panel is adaptable, helpful, and have various evaluations of solidarity and sturdiness.

2.Fluorocarbon(PVDF) Coating:

Fluorocarbon(PVDF) covering is the single component that has the effect between this sort of panels and other aluminum composite panels. This material is an amazing enhancement to aluminum. It improves its general highlights. PVDF is a blend of various segments, including fluorocarbon tars which are the key fixing. Moreover, it contains liquor, paint, fluorine compound, and ester dissolvable. The job of the PVDF covering is to give more quality and protection from the panel.

3.Cladding:

PVDF aluminum composite panel items have a wide territory of use. They are normally utilized as cladding. As these panels come in various thicknesses, are normally climate safe, and have awesome mechanical properties, they are ideal for building outsides.

4.Highlights and Applications:

Above all else, the outside of the panel is considerably complimented on account of PVDF. The covering is answerable for giving the most extreme levelness and smoothness. Another significant job of the PVDF covering aluminum composite panel is to make the material climate safe. The highlights of Fluorocarbon(PVDF) aluminum composite panel are essentially improving the general territory of the use of this item. Fluorocarbon is additionally significant for fire-obstruction, heat protection, and sound protection. Thus, the region of use of the PVDF aluminum composite panel widens as it gets reasonable for objects requiring great fire wellbeing measures. All in all, the utilization of Fluorocarbon(PVDF) aluminum composite panel is flexible as it has an assortment of uses, including enterprises, building outsides, and notice sheets.

Fluorocarbon(PVDF) aluminum panel has a comparable assembling procedure and key highlights to the fundamental aluminum composite panel. In any case, there is one key contrast and that is the layer of PVDF in PVDF aluminum composite panel or the fluorocarbon covering that fundamentally improves its mechanical and physical properties. It additionally refines the idea of this item, making the PVDF panel one of the best ones from the gathering of aluminum panels.

- Address

No.3 Beishang New City, GongShu District, Hangzhou China

-

Phone

+86-18072735884

-

Landline

+86-571-88688170

English

English